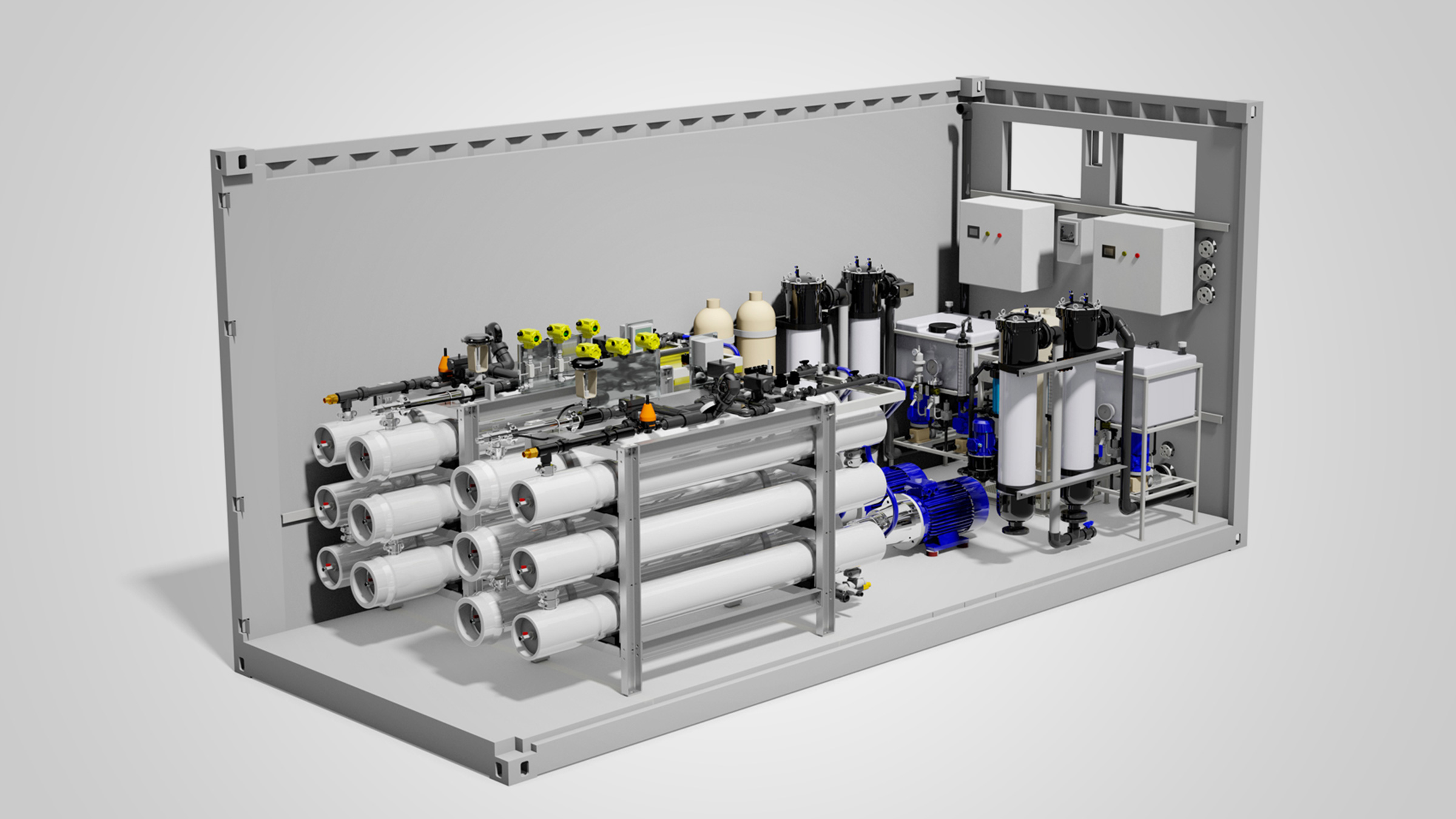

Take the difficulty out of large-scale reverse osmosis plants with containerized water treatment systems. By choosing pre-designed, module-sized plants, fully assembled in standard 20-ft and 40-ft containers with the option for a 10-ft as well, the complexity and construction of building water purification systems are no longer necessary.

Containerized water treatment systems are shipped out to where the potable water is needed. With a brief training session, commissioned workers are ready to monitor the systems to produce high-quality potable water within days of delivery.

The plant will include

- Interconnecting piping between components and systems

- Cabling and wiring of instrumentation inside the container to main control cabinet

- Operation and Maintenance manuals

- General Arrangement 3D/2D CAD drawings

Temperature (“Hot/Cold” Containers)

In hot climate areas – electrical devices and fluids must be kept below 35ºC to ensure good process performance. The temperature inside a container placed under direct sunlight can easily reach 80ºC. Therefore, we offer air-cooled insulated containers with an external sunlight rejection coating.

In cold climate areas – fluids must be kept above their freezing points and electrical equipment suffers at temperatures below 5ºC. In this case, we offer insulated containers with heating equipment to solve this issue.

What is containerized water treatment plant?

Containerized water treatment systems have a number of key advantages over built-in plant space installations:

- Short installation process

- Compact foot prints

- Simple transportation

- Mobile which is convenient for construction locations

Where are containerized water treatment systems used?

Whether your application is drinking, process, or wastewater. An on-site containerized water or wastewater treatment system is more practical and cost-effective instead of buying treated water or discharging the wastewater to water treatment facilities to remove harmful contaminants from the water. Here are some industries that employ the most use of containerized water treatment systems:

- Public Delivery

- Mining

- Military

- Agriculture

- Disaster Relief

- Swimming Pools

- Power & Energy

- Wastewater

What is mobile water treatment plant?

Mobile water treatment and purification plants are designed to cover an emergency, temporary solutions such as construction sites or long-term water treatment requirements. These mobile systems are installed inside seaworthy 20 or 40 ft containers or in combination to form complete systems with advanced water treatment and purification technologies. Those mobile treatment container units come with insulation, diamond flooring, LED lighting, climate control, and service hatches. Our mobile or containerized solutions use brackish or seawater reverse osmosis, ion exchange, ultrafiltration systems, multimedia filtration, and MBR technologies, delivered through ocean or inland by trailers.

Benefits of Mobile Water Treatment Systems

An advantageous aspect of containerized solutions is its function as a mobile water treatment system for different sites once a task is completed. These systems are made to be flexible and durable for use in any setting and come equipped with many options. Some of the aspects that our mobile water treatment systems are designed to address include:

- Treating water from any source

- Seasonal changes in water

- Quick delivery

- Changes in quality of processed water

- Temporary use until a stable system is in use